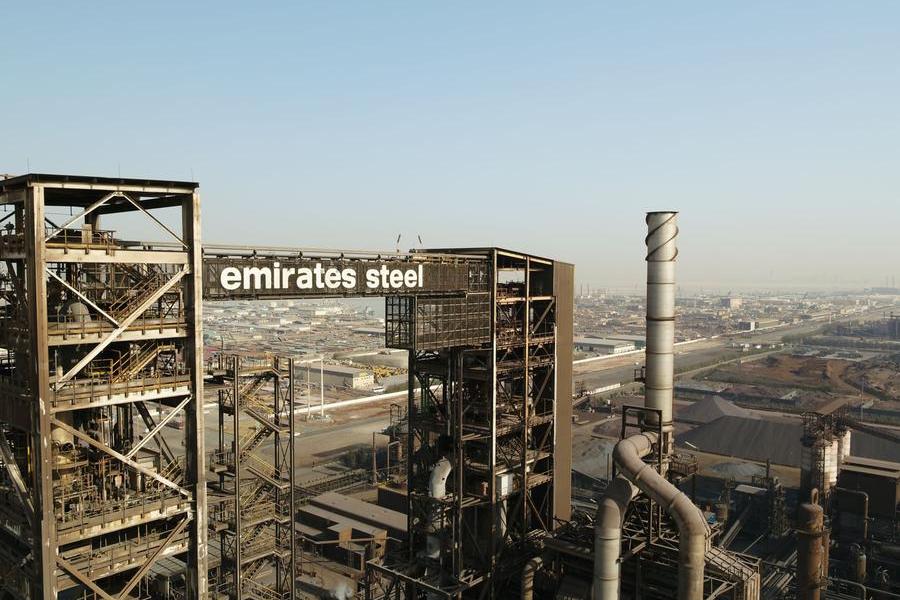

Masdar and EMSTEEL Successfully Demonstrate Green Hydrogen for Steel Production

Key Ideas

- Masdar and EMSTEEL have completed a successful pilot project showcasing the use of green hydrogen to produce green steel.

- The project aligns with Abu Dhabi's Low Carbon Hydrogen Policy and the UAE National Hydrogen Strategy to establish the country as a leading global producer of low carbon hydrogen by 2031.

- Emsteel, with 16 plants and significant production capacity, is now utilizing green hydrogen to extract iron from iron ore in the steelmaking process.

- The renewable hydrogen produced in the pilot project has been certified by Avance Labs and validated by Bureau Veritas, adhering to international standards.

Masdar and EMSTEEL, two prominent companies in the UAE, have announced the successful completion of a pilot project that demonstrates the use of green hydrogen in producing green steel. The project, now fully operational, utilizes green hydrogen to extract iron from iron ore, a crucial stage in the steelmaking process. Although specific details on production cost and quantities were not disclosed, the renewable hydrogen generated by the project has received certification from Avance Labs and validation from Bureau Veritas, ensuring compliance with international standards. Emsteel, operating 16 plants with a substantial annual production capacity, is now implementing green hydrogen in their steel and cement production. This initiative is in line with Abu Dhabi's Low Carbon Hydrogen Policy and the UAE National Hydrogen Strategy, aiming to position the UAE as a key global player in low carbon hydrogen production by 2031. The joint effort between Masdar and EMSTEEL signifies a significant step towards sustainable steel production and contributes to the overall goal of reducing carbon emissions in the industry.

Topics

Green Hydrogen

Clean Energy

Sustainability

Low-carbon

Steel Industry

Pilot Project

Renewable Certification

Latest News