BASF's Ultrason®: Pioneering Green Hydrogen Electrolyzer Technology

Key Ideas

- BASF's Ultrason® polyarylethersulfone offers exceptional stability and optimal processing for larger, robust components like frames and membranes in water electrolyzers.

- The thermoplastic's properties enable long lifetimes of electrolyzers, withstand high pressures, and provide stability under demanding conditions, contributing to the efficiency of green hydrogen production.

- BASF's partnership with the energy sector provides tailored solutions, application know-how, and technical support, positioning the company as a key player in advancing clean energy through innovative electrolyzer technology.

- Ultrason® is not only suitable for electrolyzers but also widely used in various industries due to its outstanding properties, making it a versatile and sustainable material choice.

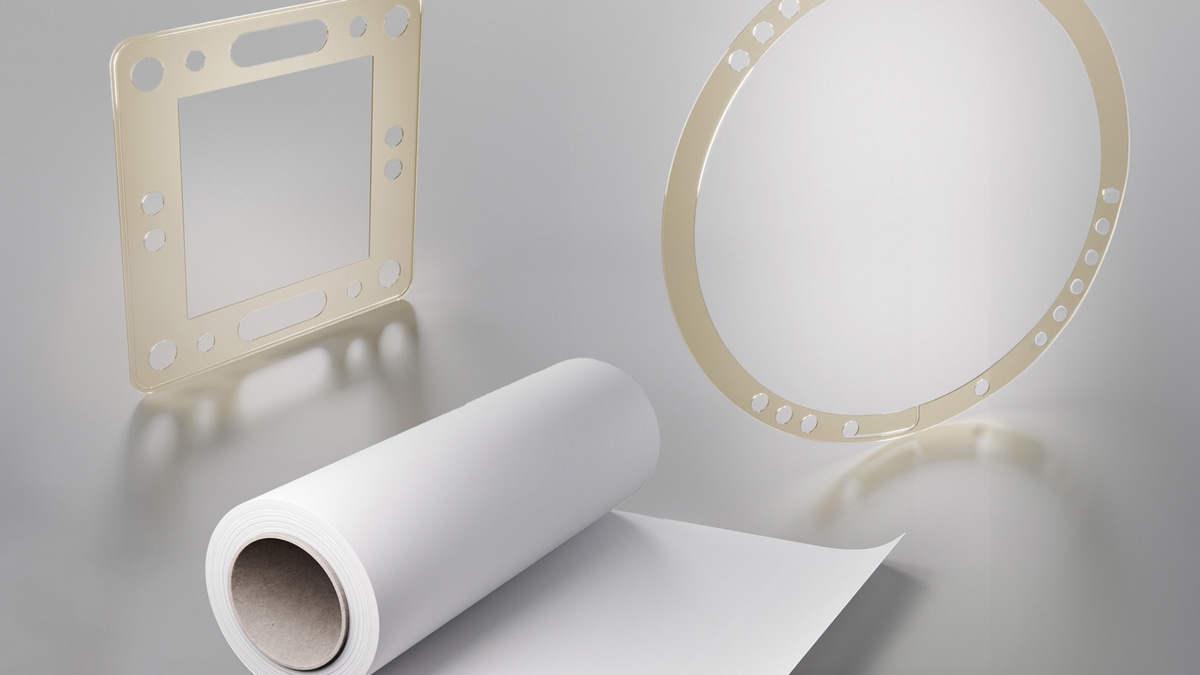

BASF is showcasing its pioneering Ultrason® polyarylethersulfone at Fakuma 2024 in Germany, emphasizing its crucial role in advancing green hydrogen electrolyzer technology. The company offers a unique partnership to the energy sector by providing a tailored portfolio of polyarylethersulfones for components in water electrolyzers used for green hydrogen production. BASF's deep expertise in injection-molding applications and membrane casting supports customers in upscaling electrolyzer technology, contributing to the transition to clean energy. Ultrason® grades are showcased for frames, gaskets, and separator membranes, offering exceptional temperature and chemical resistance. These properties make Ultrason® ideal for various electrolyzer types, ensuring long lifetimes and high efficiency. The thermoplastic's ability to withstand high pressures and provide stability under demanding conditions leads to the production of lower-weight electrolyzers with increased design flexibility. BASF's commitment to sustainability is evident through its focus on plastics' journey from production to recycling, aligning with the circular economy. Ultrason® is renowned for its excellence not only in electrolyzers but also in other industries due to its extraordinary property profile. BASF's performance materials division, achieving global sales of €7.2 billion in 2023, is driving the sustainability transformation in plastics by co-creating innovative solutions with customers worldwide.

Topics

Production

Green Technology

Energy Sector

Membrane Technology

Polymer Industry

Sustainability Transformation

Plastic Innovations

Latest News