Transforming Hydrogen Economics: Tokyo University of Science's Palladium Catalyst Breakthrough

Key Ideas

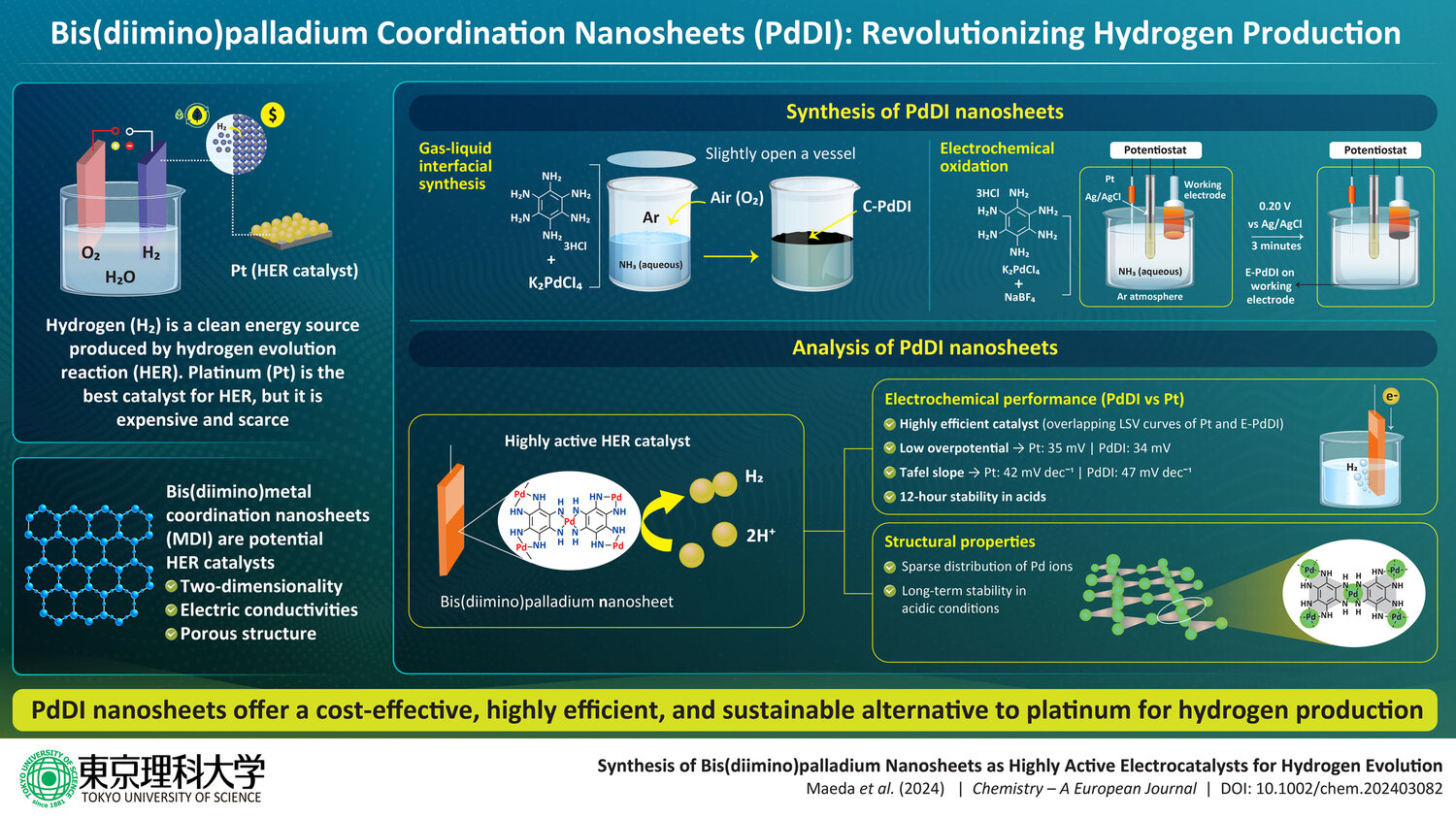

- Tokyo University of Science researchers developed a palladium-based catalyst, PdDI, reducing platinum usage by 90% in hydrogen production, enhancing cost-effectiveness.

- The catalyst demonstrates durability, operating efficiently for 12 continuous hours in acidic environments, indicating suitability for industrial applications.

- Scalability is a key feature, with two synthesis methods developed for efficient large-scale production, potentially benefiting various industries adopting hydrogen technology.

- By mitigating supply chain risks and reducing material costs, the innovation could drive the widespread adoption of hydrogen across key industries, making it more economically viable.

Researchers at Tokyo University of Science have made a significant breakthrough in industrial hydrogen production by developing a palladium-based catalyst, PdDI, that matches platinum's efficiency but uses 90% less precious metal. This innovation addresses one of the major cost barriers to hydrogen adoption, potentially making it more economically feasible for key industries. The catalyst's electrochemical performance closely resembles that of platinum, offering a cost-effective alternative for large-scale applications. Its durability and scalability make it suitable for industrial use, with the catalyst showing stability over 12 hours of continuous operation in harsh conditions. The development of two synthesis methods allows for efficient large-scale production, catering to industrial manufacturing needs. By reducing material costs and enhancing scalability, this breakthrough could benefit automotive manufacturers, hydrogen producers, and electrode manufacturers involved in hydrogen technology. Furthermore, diversifying material sources away from platinum reserves can strengthen supply chain resilience in the clean energy transition, providing businesses with more secure and cost-effective hydrogen investments.