Enhancing Sustainable Fine Chemical Synthesis Through Scalable Flow Biocatalysis

Key Ideas

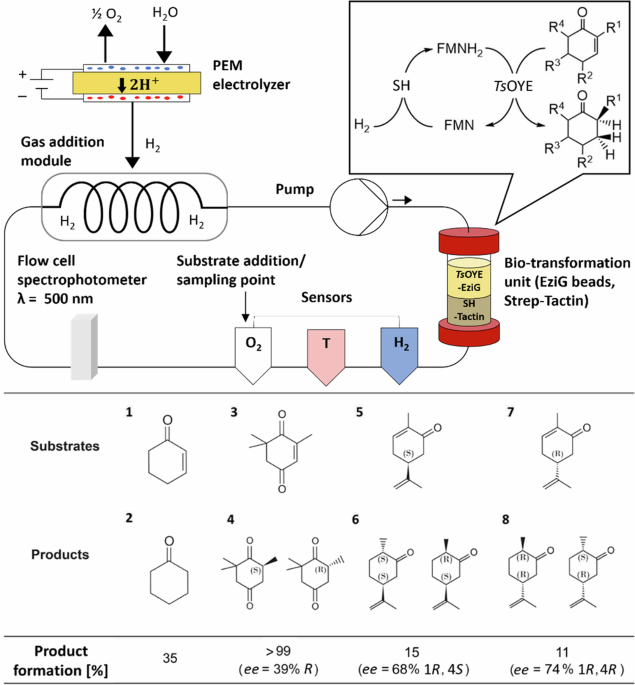

- Development of a scalable flow system using immobilized enzymes for flavin-dependent biocatalysis demonstrates remarkable stability and reusability, achieving high conversion rates.

- Integrating a soluble hydrogenase enables H2-driven regeneration of the enzyme cofactor, showcasing significant potential for advancing sustainable processes in fine chemical synthesis.

- Biocatalysis in continuous flow offers improved control over reactions, minimizes waste generation, and enhances efficient energy use, presenting a promising methodology for pharmaceutical and fine chemical sectors.

The article discusses the development of a scalable flow system for fine chemical production using biocatalysis. The system integrates immobilized enzymes, including a flavin-dependent Old Yellow Enzyme (OYE) and a soluble hydrogenase, to enable H2-driven regeneration of the enzyme cofactor. Molecular hydrogen is produced through water electrolysis and introduced into the flow system, achieving over 99% conversion rates for various reactions. This electro-driven continuous flow system shows stability, reusability, versatility, and selectivity in reducing cyclic enones, with the potential for further applications in sustainable processes. The article emphasizes the benefits of continuous flow biocatalysis in improving reaction control, minimizing waste, and enhancing energy efficiency in pharmaceutical and fine chemical synthesis.

Topics

Electrolyzer

Renewable Energy

Sustainable Processes

Biocatalysis

Continuous Flow

Enzyme Immobilization

Fine Chemicals

Enzyme Regeneration

Asymmetric Reduction

Latest News