Continental Innovates Hydrogen FCEV Cooling Systems with Synthetic Rubber

Key Ideas

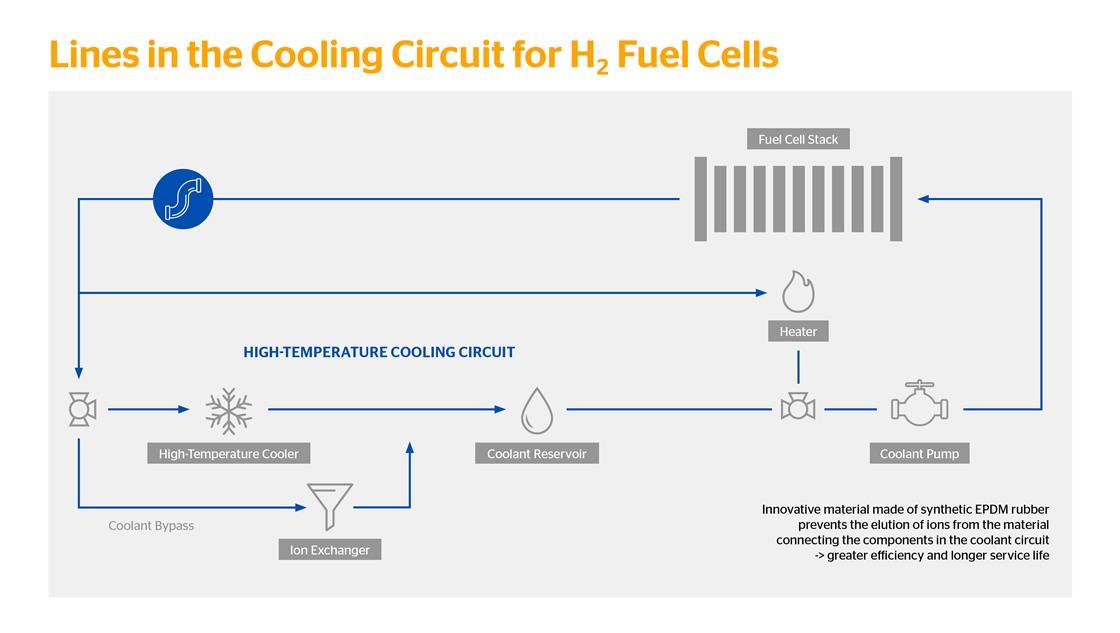

- Continental has developed a new line for hydrogen fuel cell electric vehicle cooling systems using synthetic rubber to reduce ion transfer, improving component longevity.

- The OESL business area of Continental combines material expertise to tailor elastomers, thermoplastics, and metals for hydrogen powertrains, addressing challenging requirements.

- The innovative solution creates a thermoplastic barrier layer to enhance safety by minimizing flammable hydrogen-air mixtures and reducing fuel loss, potentially extending the vehicle's range.

- Continental is making its OESL department independent to provide support to manufacturers in developing new technologies for hydrogen and battery drive systems in commercial vehicles.

Continental has introduced a new line aimed at enhancing hydrogen fuel cell electric vehicle (FCEV) cooling systems through the utilization of synthetic rubber and a blend of other materials. This development aims to mitigate the transfer of ions into the cooling circuit, ultimately contributing to the longevity of specific powertrain components. Harald Kreidner, head of research and development at ContiTech's business area original equipment solutions (OESL), emphasized the challenging requirements of permeation resistance, anti-static properties, and high pressure in this innovative solution. By amalgamating material expertise, including elastomers, thermoplastics, and metals, Continental aims to customize these components for hydrogen powertrains.

Mark Klein-Hietpas, director of commercial vehicle sales in the OESL business area, highlighted Continental's wealth of experience as a system partner for media circuits and engine mounts, emphasizing the benefits for customers in the joint development of various components for hydrogen and battery drive systems in commercial vehicles. The company's research and development efforts are crucial in adapting existing technologies to accommodate the unique demands of new drive systems.

Addressing the challenge posed by the low density of hydrogen atoms, traditional hose solutions have been deemed ineffective in preventing their release. Continental's solution incorporates a thermoplastic barrier layer to enhance safety by reducing the potential for flammable hydrogen-air mixtures and consequent fuel loss, which could potentially extend the vehicle's range. To further support manufacturers in the advancement of new technologies, Continental is restructuring its OESL department to operate independently.

Topics

Fuel Cells

Technology

Innovation

Automotive

Research

Sustainable Energy

Materials

Development

Commercial Vehicles

Latest News