Revolutionizing Safety and Efficiency: Continental's Breakthrough in Hydrogen Fuel System Technology

Key Ideas

- Continental introduces a new synthetic EPDM rubber hose with a thermoplastic barrier layer to prevent hydrogen seepage, ensuring safe vehicle operation and reducing fuel loss.

- The innovative hose material not only improves safety and range but also extends service intervals, lowering the cost of ownership for commercial vehicles.

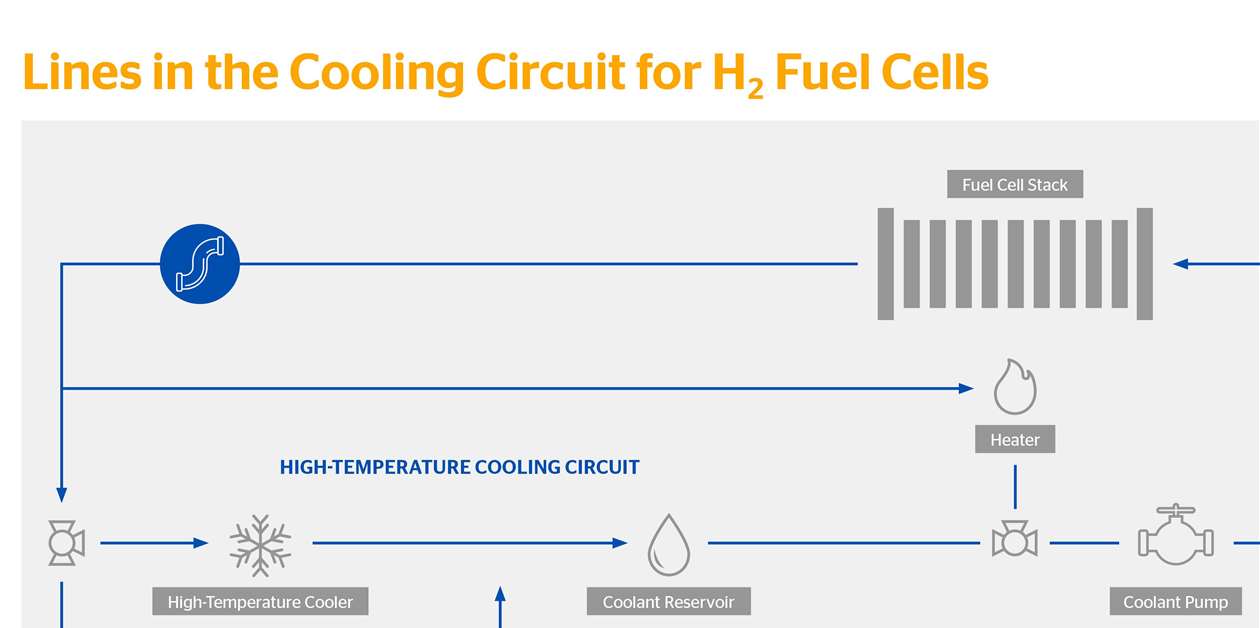

- The development by Continental's Original Equipment Solutions aims to prevent damage to fuel cell cooling systems and enhance the longevity of proton exchange membranes.

Continental has unveiled a groundbreaking development in hydrogen fuel system technology, addressing the challenges of hydrogen seepage and material damage. The company's new product, a synthetic EPDM rubber hose incorporating a thermoplastic barrier layer, aims to efficiently contain hydrogen within commercial vehicle fuel systems. By minimizing the risk of flammable hydrogen-air mixtures and reducing fuel loss, this innovation not only enhances safety but also boosts overall vehicle range. Moreover, the new hose material enables extended service intervals, contributing to reduced ownership costs. By preventing ions from entering the fuel cell cooling system and potentially damaging proton exchange membranes, Continental's solution ensures the longevity of critical components. This advancement showcases Continental's commitment to innovation and safety in the hydrogen powertrain sector, with a focus on both efficiency and material durability. The company's expertise in developing materials tailored for hydrogen applications highlights their dedication to meeting the evolving needs of the commercial vehicle industry.