Revolutionizing Green Hydrogen Production with Stainless Steel Innovation

Key Ideas

- University of Hong Kong pioneers SS-H2, a cost-effective stainless steel for green hydrogen production, offering corrosion resistance comparable to titanium at a fraction of the cost.

- SS-H2's economic impact is significant, potentially reducing material expenses by up to 40 times in industrial hydrogen production, making it a game-changer for clean energy transition.

- The innovative material broadens the horizon for green hydrogen applications in various industries like ammonia production, oil refining, steelmaking, and methanol production, contributing to lower emissions and cleaner processes.

- SS-H2 overcomes traditional stainless steel limitations with its dual-passivation layers, particularly the manganese-based layer, providing unprecedented corrosion resistance and durability for harsh environments.

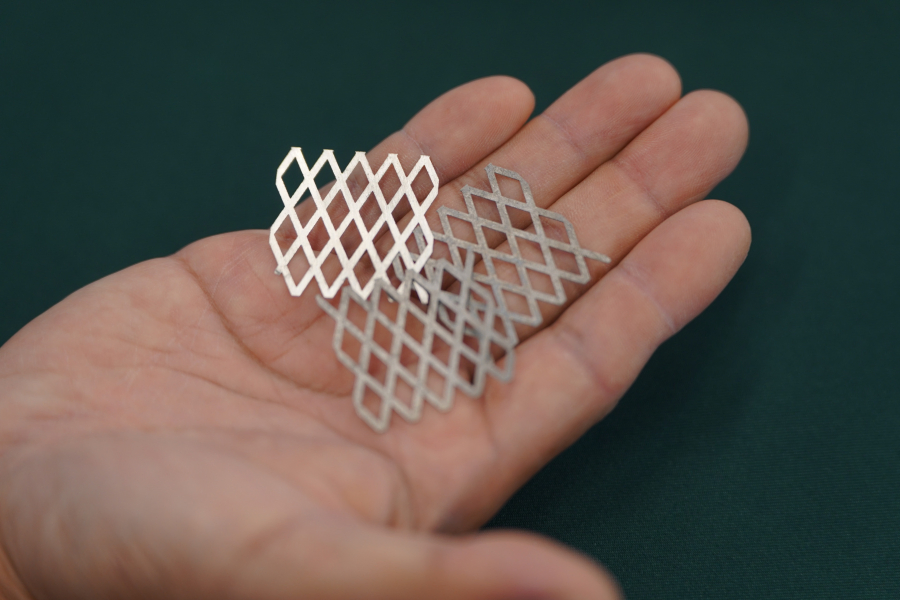

A groundbreaking stainless steel technology named SS-H2, developed at the University of Hong Kong under Professor Mingxin Huang's leadership, is revolutionizing green hydrogen production. This innovation offers a cost-effective and corrosion-resistant alternative to current electrolysis systems, potentially reducing material expenses by up to 40 times. SS-H2's dual-layer passivation mechanism, including an innovative manganese-based layer, ensures unprecedented corrosion resistance even in chloride-rich environments, expanding the possibilities for green hydrogen production from sources like seawater.

The economic implications of SS-H2 are profound, positioning it as a game-changer for industrial hydrogen production. Companies like Shell, Linde, and Bloom Energy are already incorporating green hydrogen into their operations. SS-H2's application extends beyond hydrogen production to various industries like ammonia production, oil refining, steelmaking, and methanol production, offering cleaner processes and lower emissions.

Professor Huang's team's dedication to material science has led to transformative innovations, with SS-H2 poised to drive down costs and emissions in the global transition to sustainable energy. The material's transition from the laboratory to industry marks a significant step towards large-scale applications, highlighting its potential to shape a more sustainable energy future by addressing urgent global challenges.

Topics

Green Hydrogen

Renewable Energy

Innovation

Sustainability

Cost Efficiency

Industrial Applications

Economic Impact

Material Science

Global Transition

Latest News