Innovative Membrane Dehydration for Sustainable Clean Fuels

Key Ideas

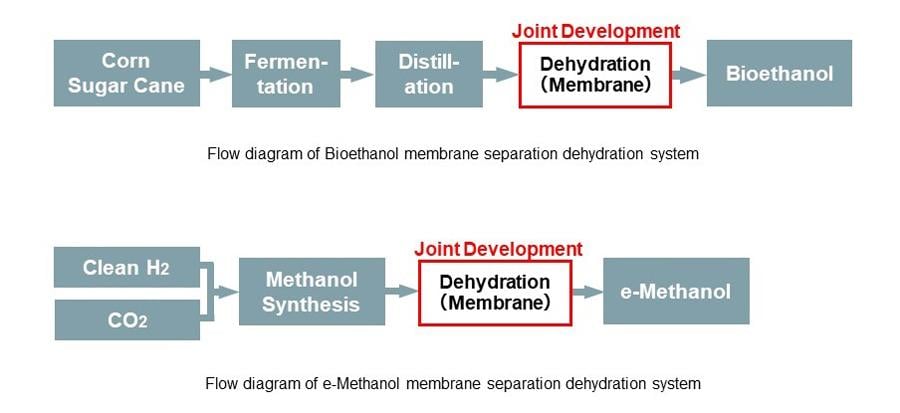

- MHI and NGK collaborate to develop membrane dehydration systems for bioethanol and eMethanol, aiming to optimize manufacturing efficiency and reduce costs.

- Bioethanol, derived from plants like corn and sugarcane, is a widely used automotive fuel in the U.S. & Brazil, contributing to sustainable aviation fuel.

- eMethanol, a clean marine fuel, is gaining attention; the new membrane separation system will replace energy-intensive dehydration processes.

- Both companies are dedicated to carbon neutrality goals, striving to commercialize hydrogen-free bioethanol and eMethanol to support a sustainable world.

Japanese companies Mitsubishi Heavy Industries (MHI) and NGK INSULATORS (NGK) have announced a partnership to develop innovative membrane dehydration systems for bioethanol and eMethanol. These systems aim to improve manufacturing processes, reduce costs, and enhance efficiency. Bioethanol, a clean fuel sourced from plants such as corn and sugarcane, is extensively used in countries like the United States and Brazil and is crucial for sustainable aviation fuel. On the other hand, eMethanol, an emerging clean fuel especially for marine purposes, is also receiving significant attention.

The project will see MHI leveraging its expertise in methanol and chemical plant delivery, along with NGK's knowledge in ceramic membrane technology. The membrane separation systems developed will revolutionize the dehydration processes in bioethanol and eMethanol production, replacing energy-intensive methods. MHI Group has set a target to achieve carbon neutrality by 2040 and aims to play a vital role in decarbonization through the development of hydrogen-free bioethanol and eMethanol manufacturing processes.

NGK Group is equally committed to sustainability and has outlined a 'Carbon Neutrality Strategic Roadmap' with a focus on developing technologies related to hydrogen and carbon dioxide capture, utilization, and storage. This collaboration follows a recent partnership between MHI and NGK to work on a hydrogen purification system using membrane separation. The new technology is envisioned to support a hydrogen and ammonia supply chain for efficient high-volume transport, aligning with the shared goal of early commercialization.