Laying the Foundation for Hydrogen: The Importance of a Process Digital Twin in Pre-FEED Phase

Key Ideas

- Developing a process digital twin during pre-FEED is crucial for establishing a digital twin for a hydrogen project.

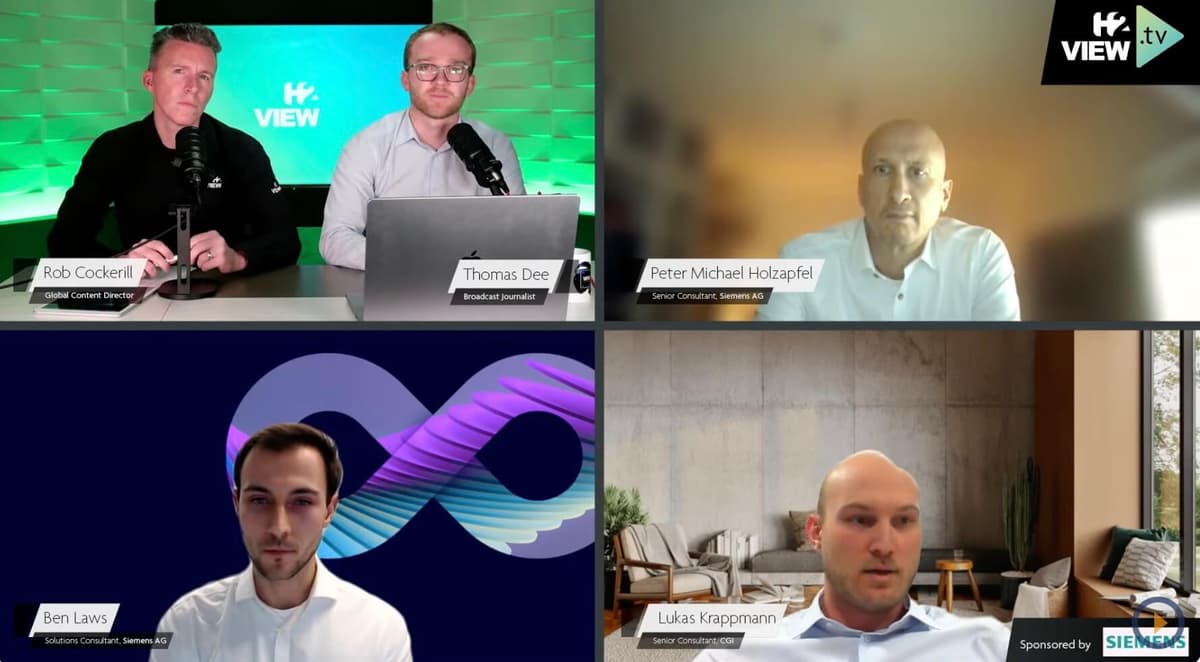

- Ben Laws from Siemens AG highlights the importance of building a model of the process at the project stage.

- A process digital twin is a great starting point as it requires minimal information to begin, irrespective of vendor selection.

- This approach streamlines the initiation of hydrogen projects by eliminating the need for extensive engineering data upfront.

Developing a process digital twin during the pre-front-end engineering design (FEED) phase is highlighted as a critical initial step in establishing a comprehensive digital twin for hydrogen projects. In a recent H2 View webinar, Ben Laws, a Solutions Consultant at Siemens AG, emphasized the significance of creating a model of the process at the project stage. Referred to as a process digital twin, this model serves as a foundational element that kickstarts the project without the necessity of finalizing vendors or accumulating extensive engineering data beforehand. This streamlined approach significantly simplifies the commencement of hydrogen initiatives, enabling stakeholders to initiate projects efficiently and with minimal initial requirements. By leveraging digital twins in the pre-FEED phase, organizations can lay a solid groundwork for successful hydrogen projects and foster innovation in the field.