Innovative Nuclear Power: Revolutionizing Heat Transfer and Hydrogen Production

Key Ideas

- New nuclear reactors employing low pressure liquids like sodium or molten salt can reach temperatures of 700°C, increasing electric power generation efficiency.

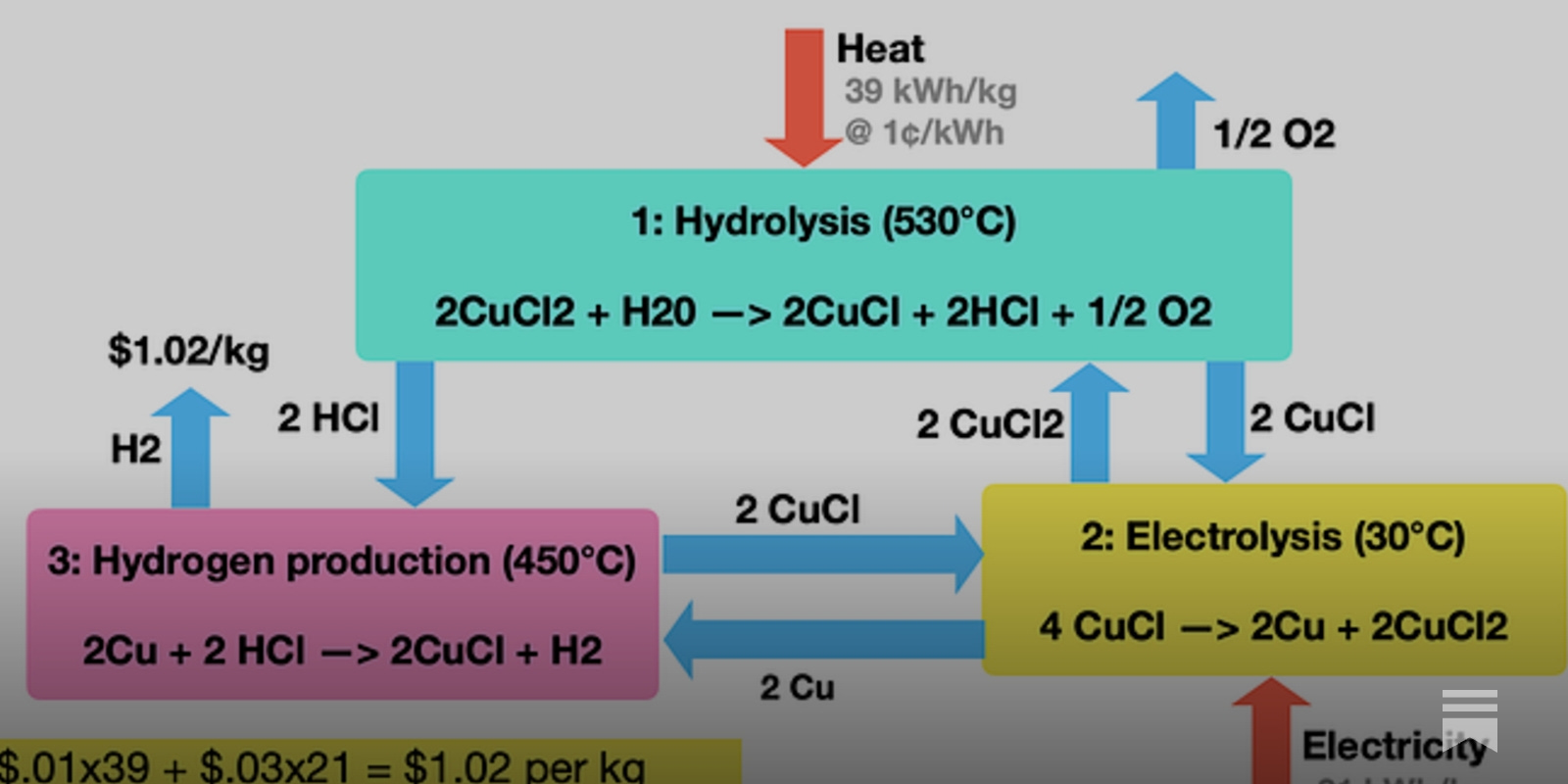

- Innovative Cu-Cl process for splitting water into H2 and O2 has been demonstrated at lab scale, aiming for a cost as low as $0.75 per kilogram of hydrogen.

- Companies like Topsoe and FuelCell Energy are making strides in hydrogen production using SOECs, achieving low electric power costs per kg of hydrogen.

- Future nuclear hydrogen production is expected to cost below $2 per kilogram, with projections indicating costs dropping closer to $1 by 2050.

The article delves into the advancements in nuclear power technology that are reshaping energy generation and hydrogen production. Traditional nuclear power plants are transitioning to utilize low pressure liquids like sodium or molten salt, enabling higher temperatures and increased efficiency in electric power generation. These novel reactors are capable of reaching temperatures of 700°C, offering improved heat transfer mechanisms.

Moreover, a groundbreaking Cu-Cl process has been developed for splitting water into hydrogen and oxygen. This innovative process, involving three chemical reactors operating at different temperatures, has the potential to produce hydrogen at a cost as low as $0.75 per kilogram. Companies such as Topsoe and FuelCell Energy are leading the way in harnessing solid oxide electrolysis cells (SOECs) to produce hydrogen, with Topsoe claiming a remarkable 93% conversion efficiency.

Despite challenges like intermittent energy sources affecting SOEC lifetimes and raising costs, nuclear power stands out as a reliable and cost-effective energy source for hydrogen production. The article also discusses a new hydrogen company that aims to utilize heat energy to split hydrogen from water, projecting future production costs to drop below $2 per kilogram and possibly reach $1 by 2050.

The current predominant method of hydrogen production, steam methane reforming (SMR), emits large amounts of CO2 and is relatively costly. In contrast, nuclear hydrogen production shows promise in significantly reducing costs and emissions associated with traditional methods. However, challenges in hydrogen distribution and transportation, like energy-intensive compression and liquefaction processes, remain areas of concern.

The article emphasizes the positive outlook for the future of nuclear hydrogen production, highlighting the transformative potential of innovative technologies and cost-efficient processes in shaping the energy landscape.

Topics

Fuel Cells

Energy Efficiency

Cost Efficiency

Nuclear Power

Research Funding

Hydrogen Production

Heat Transfer

SOECs

Latest News