Breakthrough in Hydrogen Production Efficiency and Durability at BlueScope Steel

Key Ideas

- CSIRO's electrolyser pilot at BlueScope Steel's facility in Port Kembla has successfully demonstrated efficient hydrogen production using solid oxide electrolysis technology.

- The tubular solid oxide electrolysis technology operates at high temperatures and utilizes waste heat, resulting in significant electricity savings of up to 30% compared to traditional electrolysers.

- Renewable equipment manufacturer Hadean Energy has licensed the technology and is testing its durability for commercialization, with plans for a large-scale industrial pilot.

- The success of the pilot marks a major step towards decarbonizing hard-to-abate industries, showcasing the potential for widespread adoption of the innovative hydrogen production method.

A recent pilot conducted by CSIRO at BlueScope Steel's Port Kembla steelworks in New South Wales has shown impressive results in hydrogen production efficiency and durability. The trial, lasting 1,000 hours, utilized CSIRO's tubular solid oxide electrolysis (SOE) technology, which differs from conventional electrolysers by incorporating both electricity and waste heat for enhanced efficiency. By operating at high temperatures close to 800°C and leveraging waste heat from industrial processes, the SOE technology achieved a remarkable electricity input of less than 36 kWh per kilogram of hydrogen, a significant improvement over traditional methods. This breakthrough could revolutionize the hydrogen industry by reducing production costs and advancing sustainability goals.

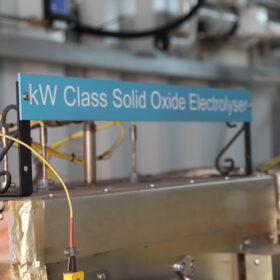

Following the successful pilot, Hadean Energy has obtained a license for CSIRO's SOE technology and is currently evaluating its long-term performance for potential commercialization. The positive outcomes from the trial have positioned Hadean Energy to showcase a 5 kW demonstration unit as part of the Australia-UK Renewable Hydrogen Innovation Partnerships, signaling a crucial step towards industrial-scale implementation. Chris Rowland, CEO of Hadean Energy, emphasized the cost-effectiveness of the SOE technology due to its simplified manufacturing process and readily available materials. The validation of the technology in an operational setting signifies a significant advancement in readiness for commercial use and highlights the potential for decarbonizing challenging industrial sectors.

Overall, the successful demonstration of the tubular SOE technology at BlueScope Steel marks a transformative development in hydrogen production, with implications for enhancing energy efficiency, reducing carbon emissions, and driving innovation in sustainable industrial practices.

Topics

South America

Renewable Energy

Technology

Sustainability

Research

Steel Industry

Commercialization

Industrial Innovation

Electricity Efficiency

Latest News