InnovationPulsing: Revolutionizing Green H2 Production Efficiency

Key Ideas

- InnovationPulsing holds the potential to significantly reduce the costs of green hydrogen production.

- The technology claims to achieve 50% efficiency gains in commercial electrolysers, which could revolutionize the industry.

- However, some skeptics argue that such gains would defy the laws of physics, raising questions about the feasibility of the claims.

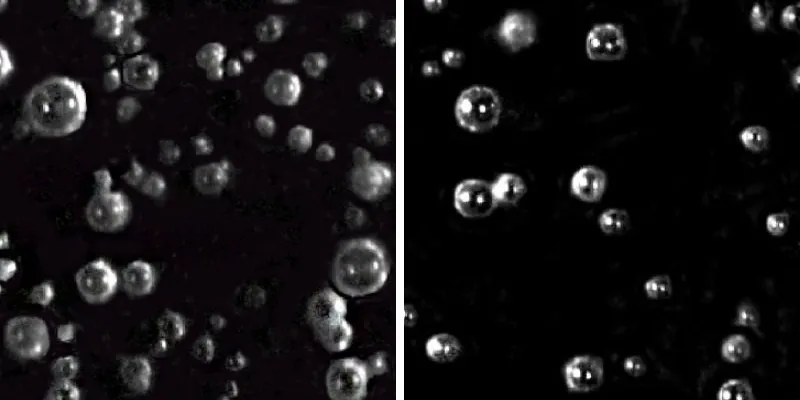

- Research and development in high-frequency pulsed electrolysis are ongoing, with promising results in improving bubble size and dispersal rates.

A recent article published on February 25, 2025, explores the concept of InnovationPulsing as a potential breakthrough for the green hydrogen industry. The technology aims to address the pressing need to reduce the costs associated with green hydrogen production. By claiming to deliver 50% efficiency gains in commercial electrolysers, InnovationPulsing has sparked both excitement and skepticism within the industry. While the efficiency gains promised by the technology could revolutionize green hydrogen production, some experts question the plausibility of achieving such significant improvements without violating the laws of physics. The article features images showcasing the difference in bubble size and dispersal rates between direct current and high-frequency pulsed electrolysis at eight volts. Ongoing research and development efforts in the field of high-frequency pulsed electrolysis offer hope for further advancements in improving efficiency and reducing costs in green hydrogen production.