Advancements in Green Hydrogen Production at Forschungszentrum Juelich

Key Ideas

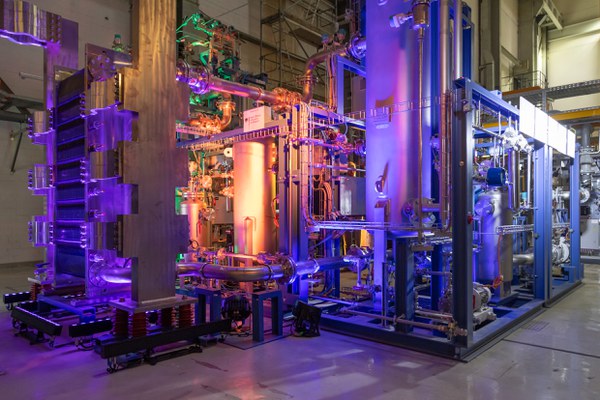

- Forschungszentrum Jülich unveiled a state-of-the-art test facility for electrolyzers to produce green hydrogen using only renewable energy.

- The facility is equipped with cutting-edge sensor technology and focuses on full-scale electrolyzers designed for industrial applications.

- The electrolyzers at the new test facility use a polymer membrane, ensuring dynamic operation suitable for renewable energy sources.

- The test facility is part of the DERIEL project coordinated by Siemens Energy, contributing to the German BMBF's H2Giga flagship project for more efficient 'made in Germany' electrolyzers.

The Forschungszentrum Jülich in Germany showcased significant advancements in green hydrogen production through the unveiling of a state-of-the-art test facility for electrolyzers. This facility, located on the Jülich campus, emphasizes the use of renewable energy for electrolysis, promoting the production of green hydrogen. Equipped with top-notch sensor technology, the facility is tailored for full-scale electrolyzers meant for industrial use. These electrolyzers utilize a polymer membrane, known as a proton exchange membrane, enabling them to operate dynamically and efficiently, especially in conjunction with renewable energy sources. The initiative is part of the DERIEL project, led by Siemens Energy and supported by the German Federal Ministry of Education and Research's H2Giga initiative, aiming to enhance the efficiency and durability of electrolyzers produced in Germany. This development marks a significant step towards sustainable and eco-friendly hydrogen production in the country.

Topics

Electrolyzer

Renewable Energy

Innovation

Efficiency

Electrolyzers

Research Center

Industrial Scale

Durability

Sensor Technology

Latest News