Tokyo University of Science's Catalyst Breakthrough: Revolutionizing Industrial Hydrogen Production

Key Ideas

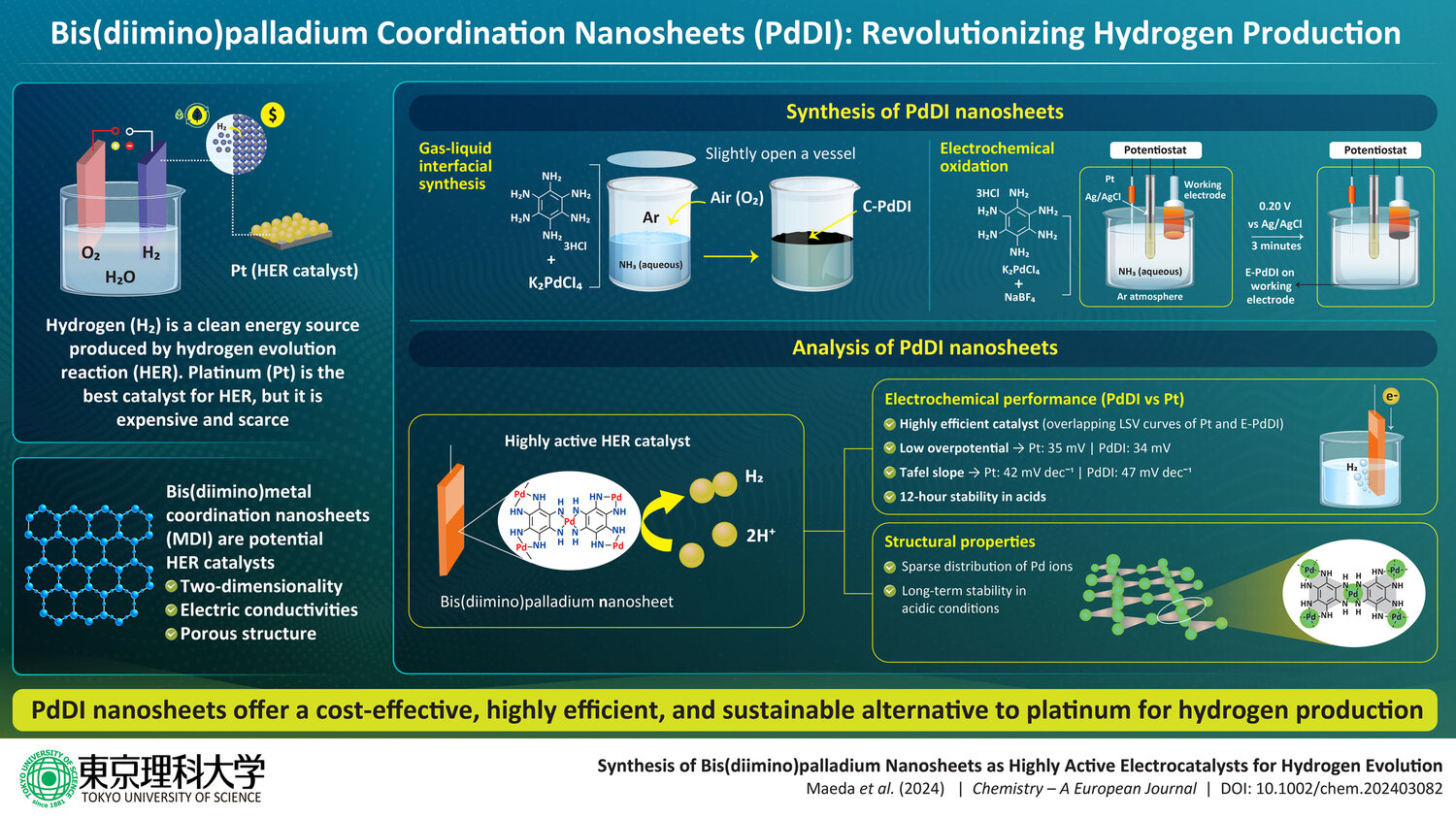

- Researchers at Tokyo University of Science have developed a palladium-based catalyst that rivals platinum's efficiency in hydrogen production, cutting precious metal usage by 90% and reducing costs significantly.

- The catalyst shows promise for industrial-scale applications, offering durability and stability over extended periods in demanding conditions, crucial for real-world implementation.

- With improved scalability and the potential to mitigate supply chain risks by reducing reliance on platinum reserves, this breakthrough has positive implications for industries adopting hydrogen technology.

Researchers at Tokyo University of Science have made a significant breakthrough in industrial hydrogen production by developing a palladium-based catalyst that addresses one of the major cost barriers in the sector. The new catalyst, known as bis(diimino)palladium coordination nanosheets (PdDI), matches platinum's efficiency in hydrogen production but uses only 10% of the precious metal, offering a cost-effective solution for large-scale applications. The catalyst's electrochemical performance closely resembles that of platinum, making it a viable alternative at a lower cost. Its nanosheet structure not only reduces the need for precious metals but also has demonstrated durability by maintaining performance over 12 hours of continuous operation in acidic environments. This durability and stability make it a promising option for industrial use. Additionally, the research team developed scalable synthesis methods that could be adapted for large-scale production, aligning with the needs of industrial manufacturing processes. The innovation has the potential to benefit various industries, including automotive manufacturers, hydrogen producers, and electrode manufacturers, by reducing material costs and improving scalability. By diversifying material sources and reducing reliance on geographically concentrated platinum reserves, the catalyst could also enhance supply chain resilience in the clean energy transition, making hydrogen investments more secure and cost-effective for businesses.

Topics

Production

Clean Energy

Research

Industrial Applications

Cost Reduction

Economic Feasibility

Supply Chain Resilience

Scalability

Catalyst Efficiency

Latest News